Airstream Travel Trailer International 2023 Tire Inspection and Storage User Manual

Tire Inspection and Storage

Before taking your trailer on a trip or when removing it from an extended storage period, make it a practice to inspect the overall condition of your tires. Check for any type of condition or damage that might result in failure. A thorough check should include both inside and outside sidewalls, tread area, and the condition of hardware such as valve stems, valve caps, and wheels. The tread should be checked for any unusual wear, cracking, penetrations, and/or cuts. An uneven wear pattern can indicate misalignment or worn suspension parts.

Since many RVs are used seasonally and sometimes stored for extended times, it is possible that tires will take many years to wear out. Tires, as any rubber product, will age over time. If tires show cracking in the sidewall or tread surfaces that are more than 2/32-in. deep, they should be replaced before your next trip or vacation. Store your RV in a cool, dry area away from major heat sources and extreme cold. An enclosed storage area is best with no exposure to electromagnetic sources such as generators or transformers. If you must keep your trailer outside, cover your tires from direct sunlight. Take your trailer to your tire dealer for service to check or correct any of these conditions.

Tire and Wheel Replacement

It is possible to replace your tires with a different size, in some instances. If there is a reason to replace your tires with a different size, make sure the following checks are made.

before the purchase:

- Does the replacement tire have the load capacity that is needed for my trailer and will it fit properly inside the wheel well?

- Will the overall diameter difference affect the braking system?

- Is the increase in air pressure compatible with the maximum rated pressure stamped on the rim?

Most trailers are towed at or near maximum loads during hot weather and then are left idle for months. In normal use, oils in the tire come to the surface during flexing and protect the rubber from ultraviolet light. But, when the trailer tires sit idle too long, natural aging may cause the rubber to crack prematurely, especially in the sidewall area. Trailer tires over 5 years old should be inspected by a tire expert for cracking and replaced even if it has no apparent tread wear.

Choosing a Tire

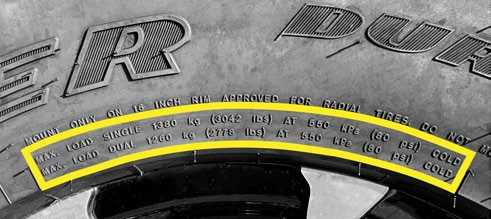

Every tire sold in the United States has a tire rating stamped on the sidewall that shows a tire’s maximum load at a defined pressure. Use the example above to help locate the max load rating in pounds (lbs) and tire pressure in pounds per square inch (psi) on your original equipment tires. Choose a tire with equal load ratings. For the tire size, inflation, and load specifications, see Section 4, Specifications.

Max Load Single vs. Max Load Dual

Max Load Single refers to the tire rating for applications with only one wheel on each end of a single axle. Max Load Dual refers to the tire rating for dually wheels, where there are two wheels on each end of an axle for a total of 4 wheels on a single axle. Don’t confuse the terms Single and Dual with Tandem. A tandem axle refers to trailers with two axles, one behind the other. For Airstream Travel Trailers, refer to the Max Load Single rating.

WARNING

Do not mismatch wheels and tires. Axle systems are installed with hubs and drums that are compatible with many wheels used in the recreational vehicle industry that have matching bolt patterns. If the original manufacturer-installed equipment is in need of replacement, the wheel manufacturer should be contacted for proof of compatibility prior to replacement and use.

Customers replacing the original with equipment that has not been tested for compatibility must ensure the replacements are compatible to the hub and drum assembly installed.

Such elements of compatibility include, but are not limited to:

- Diameter of the hub-mounting surface.

- Stud length and diameter.

- Location and number of studs.

- Center hole diameter for the wheel.

- Wheel-mounting offset from the rim center.

- Rated capacity of the wheel.

- Wheel fastener torque.

- Wheel nut size and shape.

- Impact of any added wheel accessories (such as decorative center caps) that could affect proper seating of the wheel to the hub surface.

Refer to the following table for wheel specifications.

| Wheel Specifications | ||

| Size/Center Size In Inches | Lug Pattern | Model |

| 15 x 6 / 5.5 | 6 | All Models |

| All wheels have zero offset. | ||

Lug Nut Torquing

Trailer wheels must carry much higher loads per wheel than passenger car or truck wheels. Each wheel may carry 1000 pounds and higher. Furthermore, wheels on tandem axle trailers do not steer, and are subjected to very high side load stress whenever the trailer makes a tight turn. When going around corners, especially on slow, tight turns, the wheels are subject to very strong side loads. This tends to flex the wheel and gradually loosen the wheel nuts. Although the materials and manufacturing methods are maximized for this kind of service, these extra loads can cause stress, which can result in flexing and loosening of wheel nuts.

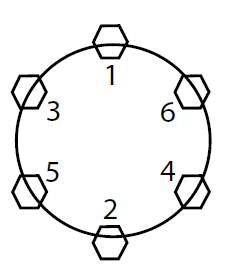

Before each trip and any time a wheel is replaced, be sure to tighten the wheel nuts, following the lug-pattern sequence shown below. If the wheel was replaced, check the torque every 5, 25, and 50 miles.

If you notice wheel wobbling or hear a rattling sound coming from a wheel, especially at low speeds, a wheel lug nut may have come loose. This problem is usually caused by improper tightening, or by faulty or damaged lug bolt threads. If suspicious of a loose lug nut, safely stop vehicle as soon as possible. Put up warning devices and check the tightness of all the lug nuts. Tighten all lug nuts to the specified torque, using a torque wrench. If stud threads are damaged or faulty, get professional service help.

NOTE

Use a torque wrench to tighten lug nuts. Tightening by hand or with an impact wrench is not recommended. Torque Aluminum Wheels to 110 ft. lbs and Steel Wheels to 100 ft. lbs.

Spare Tire Carrier

The spare tire for Airstreams is stored under the front of the trailer. The front handle of the tire carrier is a 1-in. tube protruding from under the front A-frame on the curbside. It is secured by a bracket and bolt along the inside of the A-frame rail. Removing the bolts allows the front of the tire carrier to be lowered and the spare tire to be removed.

WARNING

The spare tire carrier is designed to carry an undamaged tire and rim assembly of the type and size specified for the trailer. Never place a severely damaged wheel assembly with a damaged partial tire, or a rim only, in the carrier.

Reference Links

View Full User Guide: Airstream Travel Trailer International 2023 User Manual

Download Manuals: https://www.airstream.com/owners/manuals/

Airstream Bolt 2023 Top Accessories

[amalinkspro_table id=”32452″ new-window=”on” nofollow=”on” addtocart=”off” /]